Tel & WhatsApp: +86 183 6753 3018

Email: service@lidimachinery.com

✅ High-Speed Production: 20-45m/min output for roofing sheets & wall cladding panels

✅ Precision CNC Control: ±0.1mm tolerance for consistent C/Z/U profiles

✅ Multi-Material Compatibility: Galvanized steel, aluminum, pre-painted coils (0.3-1.5mm thickness)

✅ Heavy-Duty Construction: Hardened rollers, PLC automation, 10-15 year lifespan

✅ Custom Profiles: Design-specific roll tooling for architectural projects

Certified: CE, ISO 9001, TÜV | Applications: Pre-engineered buildings, warehouses, industrial facilities

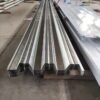

Industrial Metal Roofing & Cladding Panel Roll Forming Machine

High-Speed Precision for Architectural and Structural Applications

LIDI Machinery’s advanced roll forming system is engineered to deliver superior throughput and versatility in manufacturing roofing sheets, wall cladding panels, floor decking, and corrugated profiles. Designed for heavy-duty mass production, this machine exceeds industry standards with extended material compatibility and enhanced automation.

Applications

This machine produces a wide range of roofing and cladding products, including:

[Insert Image Gallery Here: Include technical drawings of common profiles + photos of finished panels]

Production Line Components

1. Decoiler & Feeding System

2. Leveling Unit

3. Roll Forming Section

4. Post-Cut System

5. Hydraulic & Control System

6. Safety Features

Key Performance Metrics

(Technical Specifications Table)

| Parameter | Specifications |

|---|---|

| Production Speed | 20-80 m/min (programmable with ±0.5% speed stability) |

| Material Thickness | 0.2-2.0 mm (expandable to 2.5 mm with optional reinforcement) |

| Coil Width Range | 300-1500 mm (customizable for ultra-wide profiles) |

| Yield Strength | 230-850 MPa (supports high-strength steel, aluminum alloys, and stainless steel) |

| Forming Accuracy | ±0.1 mm (laser-calibrated for critical tolerance applications) |

| Tool Change Time | <15 minutes (patented cassette-type quick-change system) |

| Cutting System | Hydraulic flying shear with ±1 mm length precision |

| Certifications | CE, ISO 9001, TÜV (complies with EU Machinery Directive 2006/42/EC) |

Primary Industrial Applications

This machine is ideal for fabricating panels used in:

Core Advantages

Extended Material Compatibility

Processes galvanized steel, pre-painted coils, stainless steel (304/316), and aluminum (including anti-scratch coated variants). Handles thinner foils (0.2mm) for lightweight panels and thicker sheets (2.0mm) for structural applications.

Enhanced Automation

Integrated non-stop stacking system with robotic arm integration (optional). PLC-controlled auto-lubrication reduces maintenance downtime by 40%.

Multi-Profile Flexibility

Pre-engineered tooling sets for C/Z/U/W profiles, trapezoidal ribs, and custom architectural shapes. 15+ standard profiles available for immediate shipment.

Video Demonstration

[Insert YouTube Video Here]

Watch our machine in action: High-speed forming of galvanized steel roofing panels with automated stacking.

Why Choose LIDI Machinery?

✅ In-Stock Machines: 20+ popular models ready for shipment within 7 days.

✅ Custom Solutions: Send your profile design (DWG/DXF/PDF) for tailored engineering.

✅ Global Support: 24/7 technical assistance with spare parts logistics.

✅ Certified Quality: CE, ISO, and TÜV certifications ensure compliance.

✅ Global Support: 24/7 technical assistance with spare parts logistics.

✅ Life-time Technical Support: We offer life-time technical support with video meetings.