Tel & WhatsApp: +86 183 6753 3018

E-posta: service@lidimachinery.com

Cold roll forming (CRF) technology enables manufacturers to create complex metal shapes with remarkable efficiency and accuracy. As someone who has managed numerous cold roll forming machine projects, I’ve witnessed firsthand how these machines can streamline processes and enhance product quality. In this post, I’ll take you through the key components of cold roll forming machines, the development techniques that drive their performance, and the diverse applications where they are making an impact.

Cold roll forming is a process that shapes metal sheets into specific profiles at room temperature (vs. hot forming). This method allows for continuous bending & shaping of a strip of metal as it passes through a series of rollers. For example, consider the production of a steel channel, which is commonly used in construction.

The process begins with a flat strip of metal, typically coiled and stored in a coiler. This coiled sheet is unspooled and fed into the series of rollers, where it undergoes a series of bending operations. The result is a finished product with high strength and precision, often achieving dimensions that meet tight tolerances.

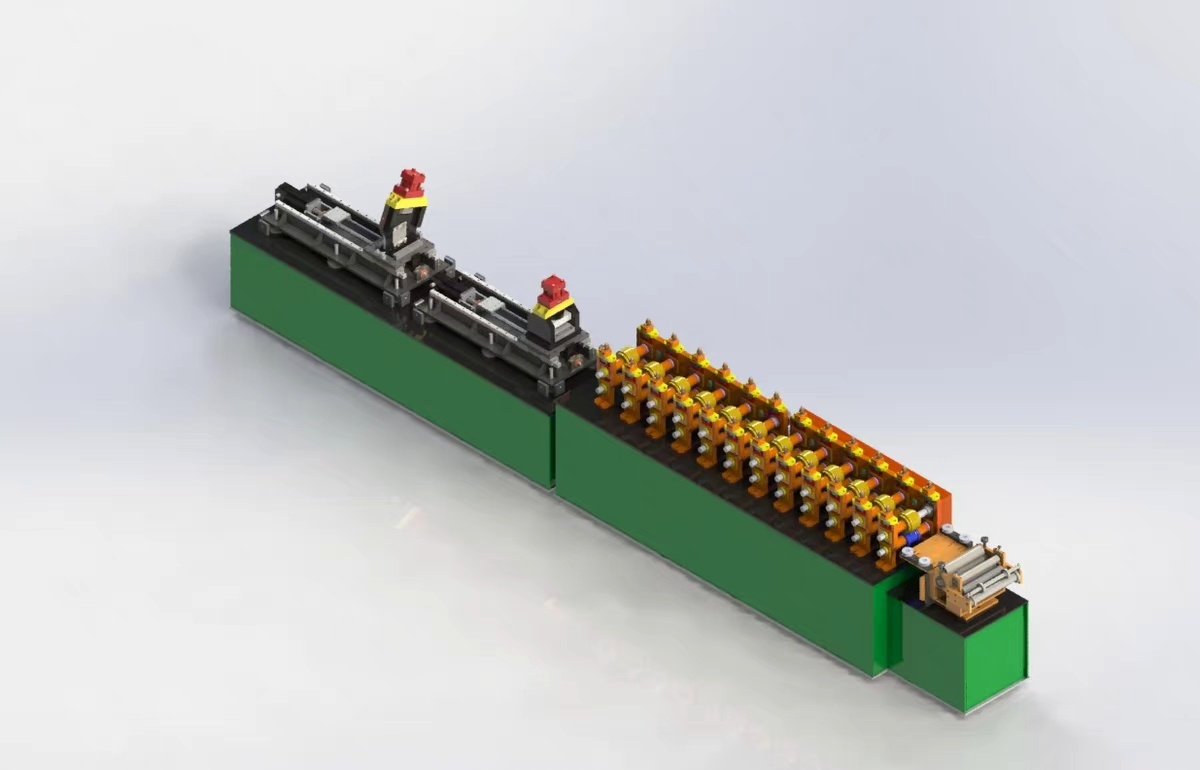

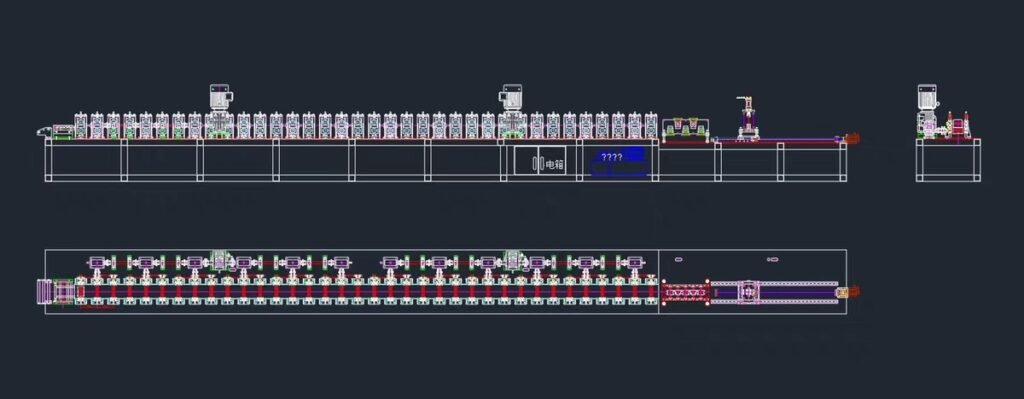

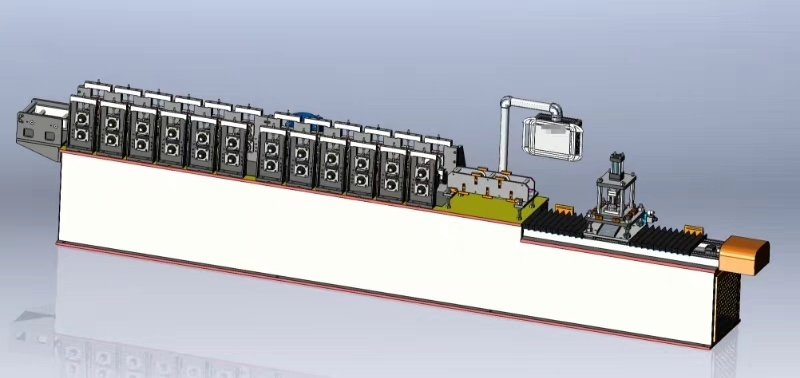

Cold roll forming machine, or cold rollformer, doesn’t refer to a single machine, it’s rather a production line that consists of a decoiler, series of rollformers, and a final cutting machine.

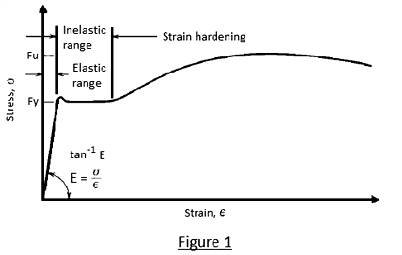

Cold roll steels show a specific yield point under tension test. The first stage is a linear elastic range where stress (σ) grows linearly with strain (ε). After the yield point, the stress holds while the strain grows steadily, that is, the stell “yields” under same stress. Common use cases should avoild the stress of steel exceeds yield point because this means the steel can’t recover to it’s base station anymore.

The functionality of a cold roll forming machine lies in its various components working seamlessly together. Here’s a detailed breakdown of these key parts and how they contribute to the overall workflow:

The feed system initiates the process by transporting the metal strip into the machine. The metal strip, typically in coil form, is unspooled and fed into a de-coiler that unwinds the material. This de-coiling step is crucial as it ensures a smooth, continuous flow of metal into the forming machine.

In our setups, we often implement automatic feed systems equipped with servo motors. These systems can control the feed rate with high precision. For example, in a project producing specialized purlins, the automatic feed system adjusts the speed based on the thickness and type of metal being used, ensuring consistency throughout the manufacturing process. The servo motor control even goes one step further by automatically communicating with the cutting machine to keep both in sync.

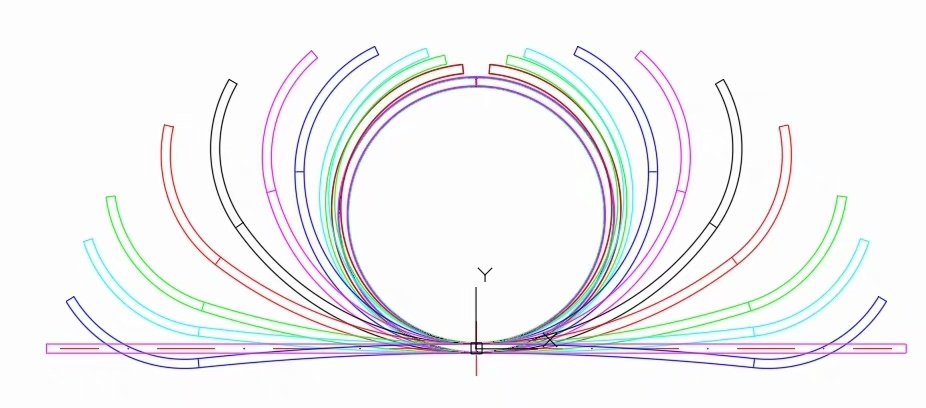

Once the metal strip is fed into the machine, it enters the roll forming section. This part of the machine consists of multiple roller stations, each designed to gradually shape the metal into the desired profile.

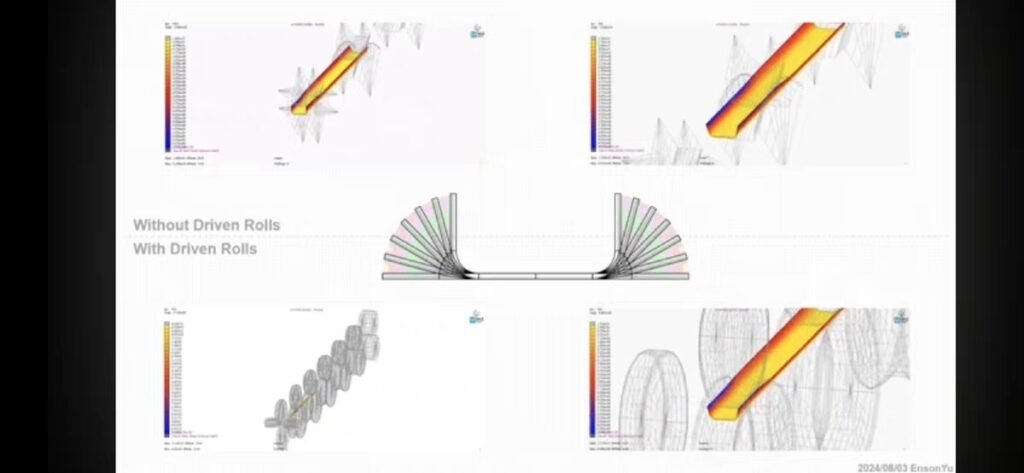

For instance, when producing C/U purlin channels, the strip passes through a series of rollers, each applying a specific bend at precise angles. As the metal moves through these stations, it is crucial that each roller is accurately aligned and positioned to ensure the final dimensions are met. Here is an image showing how a flat sheet is bended into a circular shape step by step.

After the shaping is complete, the material emerges with its final profile, ready for the next stage. This section often requires robust materials for the rollers themselves, and we’ve had great success using hardened tool steel rollers, which help reduce wear and maintain accuracy over time.

After the roll forming section, the shaped metal strip moves to the cutting system. This section typically employs shear cutting, where a cutting blade slices through the metal at predetermined lengths.

For example, when producing highway guardrails, the cutting system must deliver pieces that are consistently sized to ensure they fit together perfectly in installation. The shear cutting process provides clean edges and high accuracy, critical for safety applications.

The integration of sensors in the cutting system also plays a significant role—these sensors can detect the length of the formed product and trigger the cutting mechanism at the right moment. This automation minimizes human error and maximizes efficiency.

The control system is the brain of the operation. It often includes Programmable Logic Controllers (PLCs) from manufacturers like Siemens or Rockwell Automation, along with Human-Machine Interfaces (HMIs) for operator interaction.

The control system monitors performance across the production line, adjusting parameters such as speed and pressure automatically based on real-time feedback from the sensors. In one project, we implemented a predictive maintenance feature that alerted us to potential operational issues before they caused downtime, resulting in smoother production runs and happier clients. We are also hoping to apply AI Machine Learning tools for predictive maintenance in our next generation of cold roll forming machine control system.

Quality control is paramount in manufacturing, and thickness gauges and sensors ensure that the formed metal meets specific requirements. These devices continuously monitor the thickness of the strip as it progresses through the machine.

For instance, in a project involving solar panel framing, maintaining precise thickness was crucial to ensure the structural integrity of the panels. If the gauge detects a deviation from the specified dimensions, it can trigger an alert, allowing operators to make quick adjustments to the feed or roller settings.

BTW, usually our machines can be manually adjusted to work with a range of sheet thicknesses. For example, 1-3 mm sheets will work with the same cold roll forming machine. This offers our customers more choices in expanding their product SKUs by offering products of different thicknesses.

Finally, after the metal has been formed and cut, it enters the output section. This part of the line is responsible for handling and sorting the finished products.

This can be done manually, together with manually quality checks. But we can also help with automatic packaing. We are able to implement conveyor systems that automatically transport the produced items to designated areas for stacking or packaging. This automation reduces manual labor and speeds up the logistics of the operation. For example, in our recent work with an HVAC manufacturer, we designed a system that quickly sorted and packaged ductwork components, expediting the fulfillment process and enhancing customer satisfaction.

Creating a new cold roll forming machine involves several advanced techniques that enhance the overall performance and efficiency of the equipment. Here’s a closer look at these techniques:

The design phase begins with Computer-Aided Design (CAD) software, such as SolidWorks or AutoCAD. These tools allow engineers to create detailed blueprints of the machine components, facilitating clear communication among team members and ensuring that everyone is on the same page.

For example, in a recent project, we used SolidWorks to create a 3D model of our roll forming machine, allowing us to visualize and iterate on the design before any physical components were manufactured. This step is critical in identifying potential issues, such as interferences between components, early in the development process.

In LIDI Machinery, we will offer a comprehensive 3D model for the cold roll forming machines as part of the deliverables so customers can view their production line before it’s made. Based on my personal experience it really helps our customers understand the product.

After the CAD drawings are complete, we employ Computer-Aided Engineering (CAE) tools such as ABAQUS and COPRA. These tools simulate the roll forming process, helping us predict how the material will behave under different conditions.

In one of our projects, during CAE analysis, we discovered that a specific roller configuration could lead to excessive wear. By adjusting the design before building the machine, we prevented potential maintenance issues, saving both time and money in the long run.

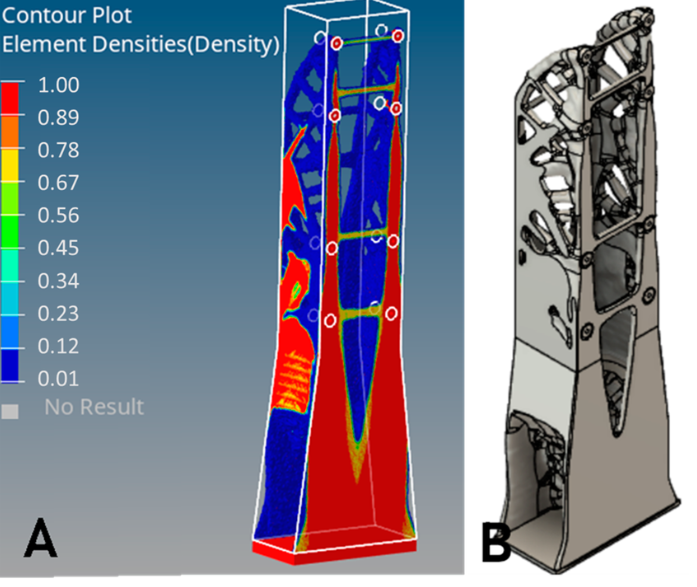

Topology optimization is a sophisticated technique used to improve the structural performance of machine components while minimizing material usage. We often use tools like OptiStruct for this purpose.

For example, while designing a frame for a new roll forming machine, we employed OptiStruct to analyze stress distribution and optimize the material layout. This not only resulted in a lighter machine but also enhanced its rigidity, ultimately improving production efficiency without compromising strength.

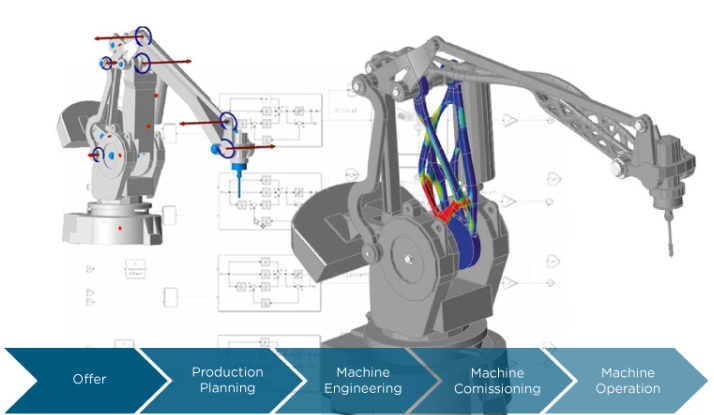

The development of advanced control algorithms is crucial for optimizing CRF machines. We often implement adaptive control techniques that enable the machine to automatically adjust based on sensor feedback.

In a recent automotive project, this adaptive control system allowed us to fine-tune the forming process in real-time, resulting in improved dimensional accuracy and reduced material waste. The ability to respond dynamically to variations in material properties is a game changer in our industry.

Integrating electronic components is essential for modern cold roll forming machines. We incorporate sensors, actuators, and IoT technology to enhance automation and enable real-time monitoring.

For instance, in a project for producing metal brackets, we utilized IoT solutions to gather performance data, which allowed us to identify trends and optimize production schedules. This approach not only improved overall efficiency but also provided valuable insights for future projects.

The sensors data can be stored in your local PC and may be used later for predictive maintenance using Machine Learning tools. LIDI Machinery is still developing this functionality and we hope to bring this to our customers ASAP.

Before manufacturing a new machine, we conduct extensive simulation testing. We use software like MATLAB and other simulation tools to validate machine performance under various conditions.

For example, in a simulation for a new cutting system, we tested its operation under different speeds and materials to ensure it would perform reliably in real-world conditions. This thorough testing phase allows us to fine-tune components and validate our designs before production begins. We can also develop Digital-Twin models if you request.

Choosing the right materials is crucial for the success of any project. We carefully evaluate factors such as strength, ductility, and cost when selecting materials.

For instance, in projects involving solar structures, we often opt for high-strength aluminum alloys that provide durability while remaining lightweight. This careful selection not only impacts performance but can also lead to significant cost savings in material and shipping.

Cold roll forming machines are incredibly versatile and find applications across a multitude of industries. Here are some key sectors and the products they commonly produce:

Welcome to visit our company! Contact us by sending us the steel profile you need and we will work on it!

Please check out our YouTube video showing a complicated steel profile (not aluminum!)