Tel & WhatsApp: +86 183 6753 3018

Email: service@lidimachinery.com

High-precision CNC beam bending system for structural steel fabrication.

✅ Smart CNC Control: Programmable angle memory for 200+ profiles

✅ Heavy-Duty Capacity: 600mm flange width / 40mm web thickness handling

✅ Multi-Material Processing: Carbon steel (S355JR), stainless steel (304/316), aluminum alloys

✅ Rapid Tooling Change: Hydraulic clamp system (<3min die swap)

✅ Energy Efficiency: 25% lower power consumption vs hydraulic competitors

Certified: CE, ISO 9001:2015, TÜV | Applications: Steel structures, crane beams, bridge girders, industrial racks

Processes I-beams, H-beams, and channels (50x50mm to 600x600mm) with ±0.5° angular accuracy. Features 3-axis servo control, 20-45 tons bending force.

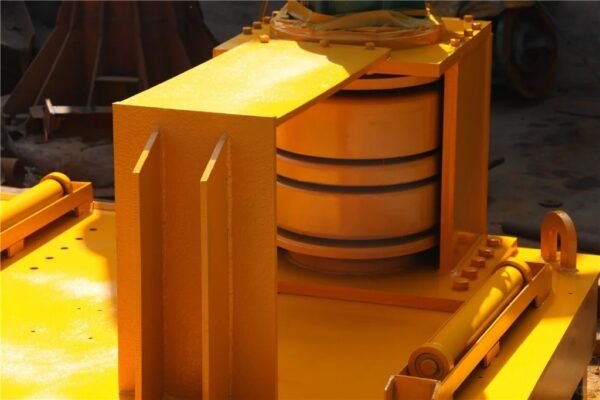

Industrial-Grade Structural Beam Forming Solution

LIDI’s advanced CNC bending system delivers millimeter-level precision for fabricating load-bearing components in compliance with EN 1993, AISC 360, and JIS G3101 standards.

Material Handling

Bending Unit

Control Module

| Parameter | Specification |

|---|---|

| Beam Section Range | H-beam: 100x100mm – 600x600mm |

| I-beam: 80x46mm – 630x180mm | |

| Material Yield Strength | 235-690MPa (ASTM A36/A572 Gr.50) |

| Bending Accuracy | ±0.5° angular / ±1mm linear |

| Ram Speed | 5-20mm/s (programmable) |

| Power Consumption | 35kW (regenerative energy recovery) |

| Certifications | CE, EN 1090-2 EXC3, TÜV ISO 12100 |

Smart Process Control

Real-time strain monitoring with AI-powered bend deduction calculation

Multi-Stage Bending

Memory 50+ complex sequences (e.g., S-curves, compound angles)

Safety Assurance

Dual emergency stops + light curtain protection

Global Compliance

Meets ASME B30.20, DIN 18800-7, and GB 50017 standards

✅ Fast Delivery: 10+ standard models in stock, ready in 7 working days

✅ Turnkey Solutions: Free FEA simulation for critical bend simulations

✅ Certified Tooling: Hardened dies (HRC 58-62) with 500,000+ cycle warranty

✅ 24/7 Support: Remote diagnostics via IoT-connected systems