Tel & WhatsApp: +86 183 6753 3018

Email: service@lidimachinery.com

✅ High-Speed Output – 15-25m/min with ±0.15mm/m laser-calibrated accuracy

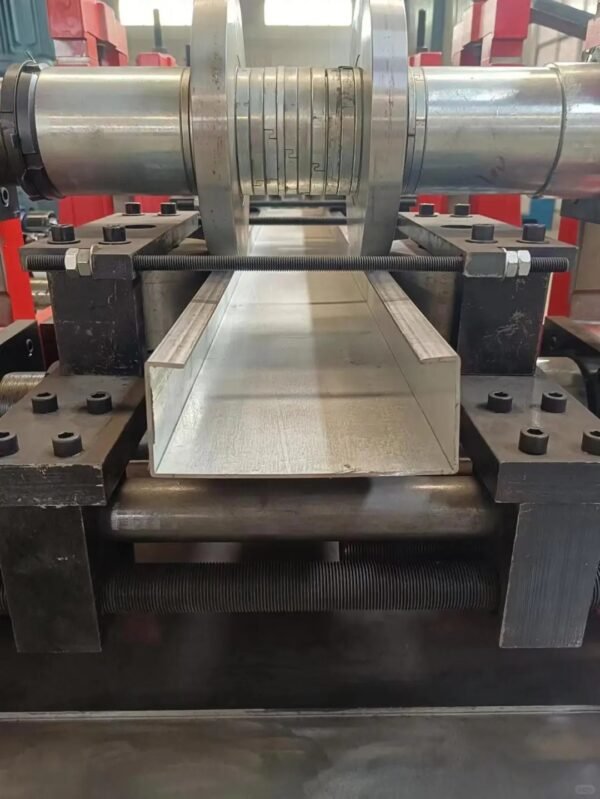

✅ Heavy-Duty Construction – Cr12MoV hardened rollers for 100,000+ hour durability

✅ Multi-Material Capacity – Processes galvanized steel (SGCC/DX51D), stainless steel & aluminum

✅ Smart Automation – Siemens PLC control & RFID tooling identification

Professional C/Z Purlin Roll Forming Machine for Steel Structure Building | 0.8-3.0mm Thickness | CE Certified | 15-25m/min Speed | Free Design Consultation

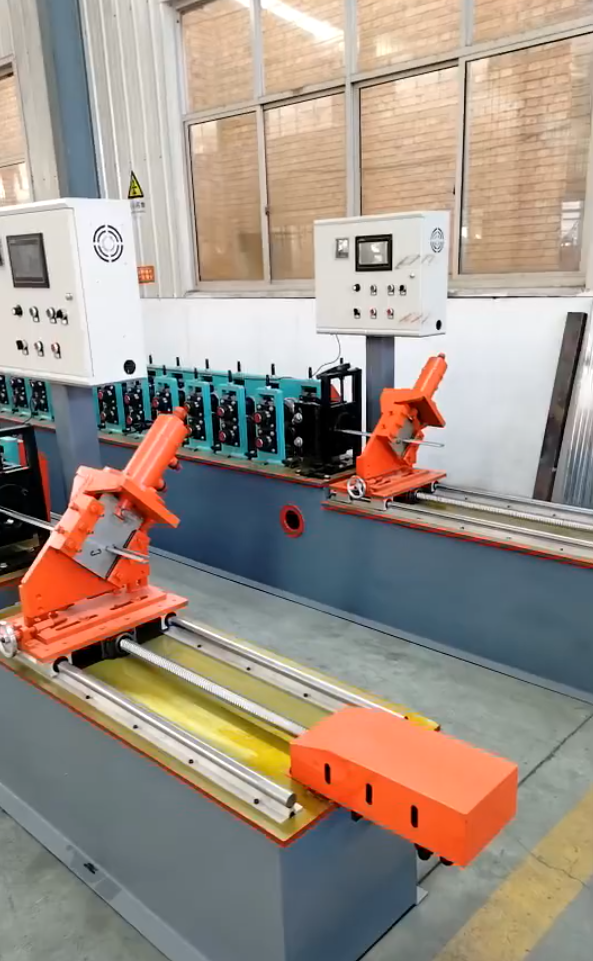

High-Speed C/Z/U/M Purlin Roll Forming Machine for Steel Structure Building

Industrial Steel Purlin Roll Forming Solution for Structural Framing

LIDI Machinery’s precision-engineered C/Z Purlin Roll Forming Machine delivers unmatched efficiency for manufacturing structural steel purlins, channels, and beams. Designed for heavy-duty production lines, this high-speed system ensures consistent quality for steel framing in commercial, industrial, and prefabricated building projects.

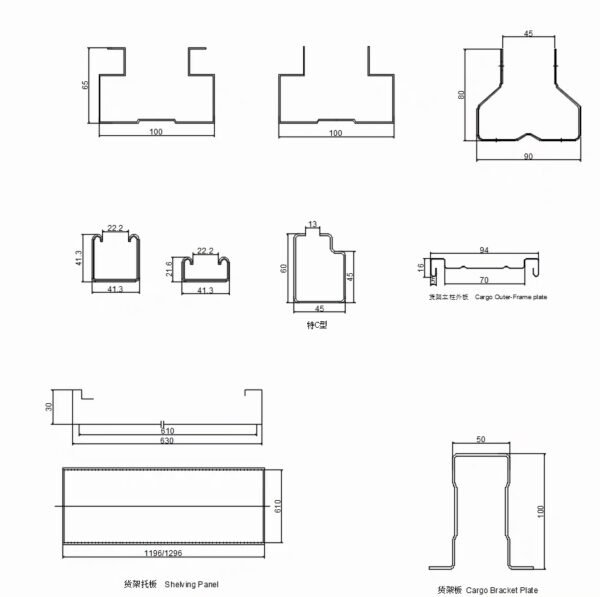

This machine specializes in producing:

[Insert Image Gallery: C/Z purlin samples, machine operation videos, structural applications]

Decoiler & Feeding System

Leveling Unit

Roll Forming Section

Cutting System

Control System

| Parameter | Specifications |

|---|---|

| Production Speed | 15-25 m/min (±0.3% speed stability) |

| Material Thickness | 0.8-3.0 mm (galvanized steel, stainless) |

| Profile Depth | 50-300 mm (C/Z/U/W shapes) |

| Coil Width | 200-800 mm (customizable) |

| Forming Accuracy | ±0.15 mm/m (laser-verified) |

| Power Consumption | 18.5kW (380V/50Hz/3Phase) |

| Certifications | CE, ISO 9001, TÜV |

✅ Ultra-Durability

✅ Smart Automation

✅ Material Flexibility

✅ Energy Efficiency

[Insert YouTube Embed Code]

Watch: High-speed forming of 2.5mm galvanized C-purlin with automatic stacking

🔧 Global Support Network

⚡ Fast Delivery

💡 Custom Solutions

📊 Performance Guarantee