Tel & WhatsApp: +86 183 6753 3018

Email: service@lidimachinery.com

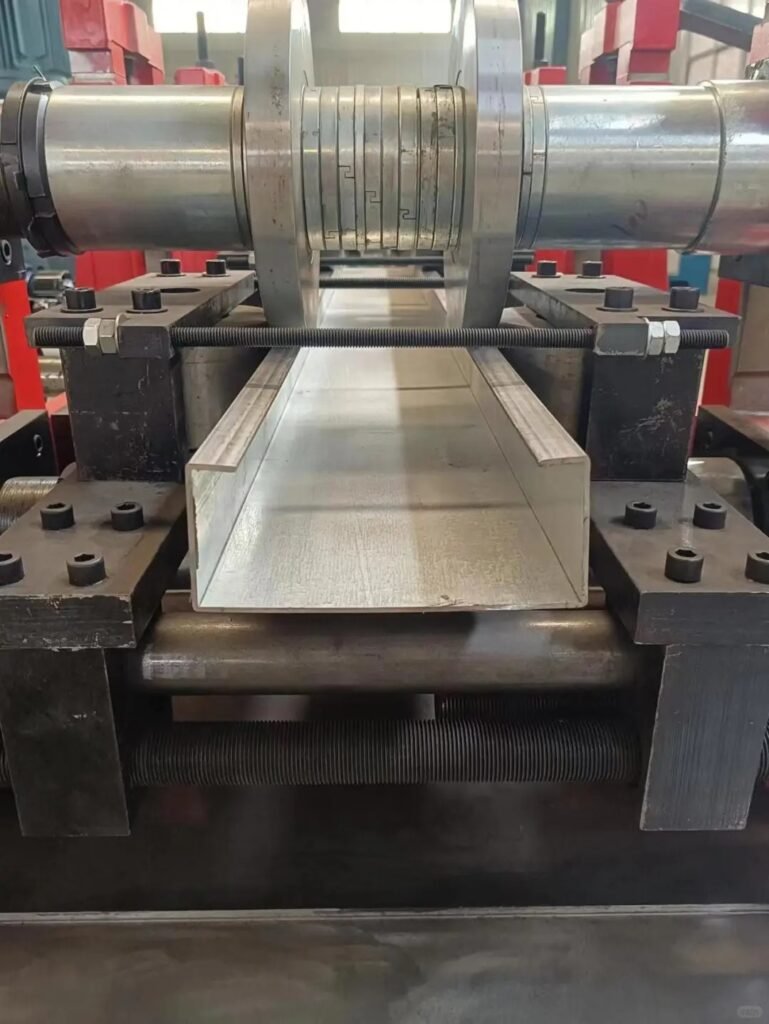

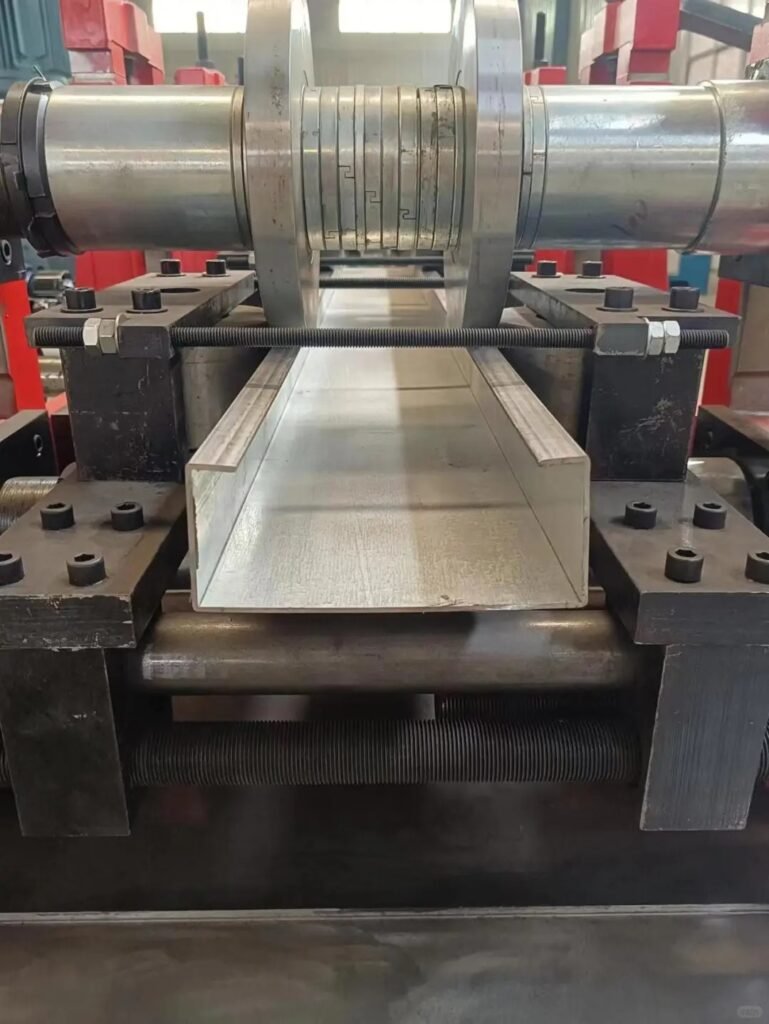

C/Z steel purlin manufacturing equipment with precision punching and cutting systems.

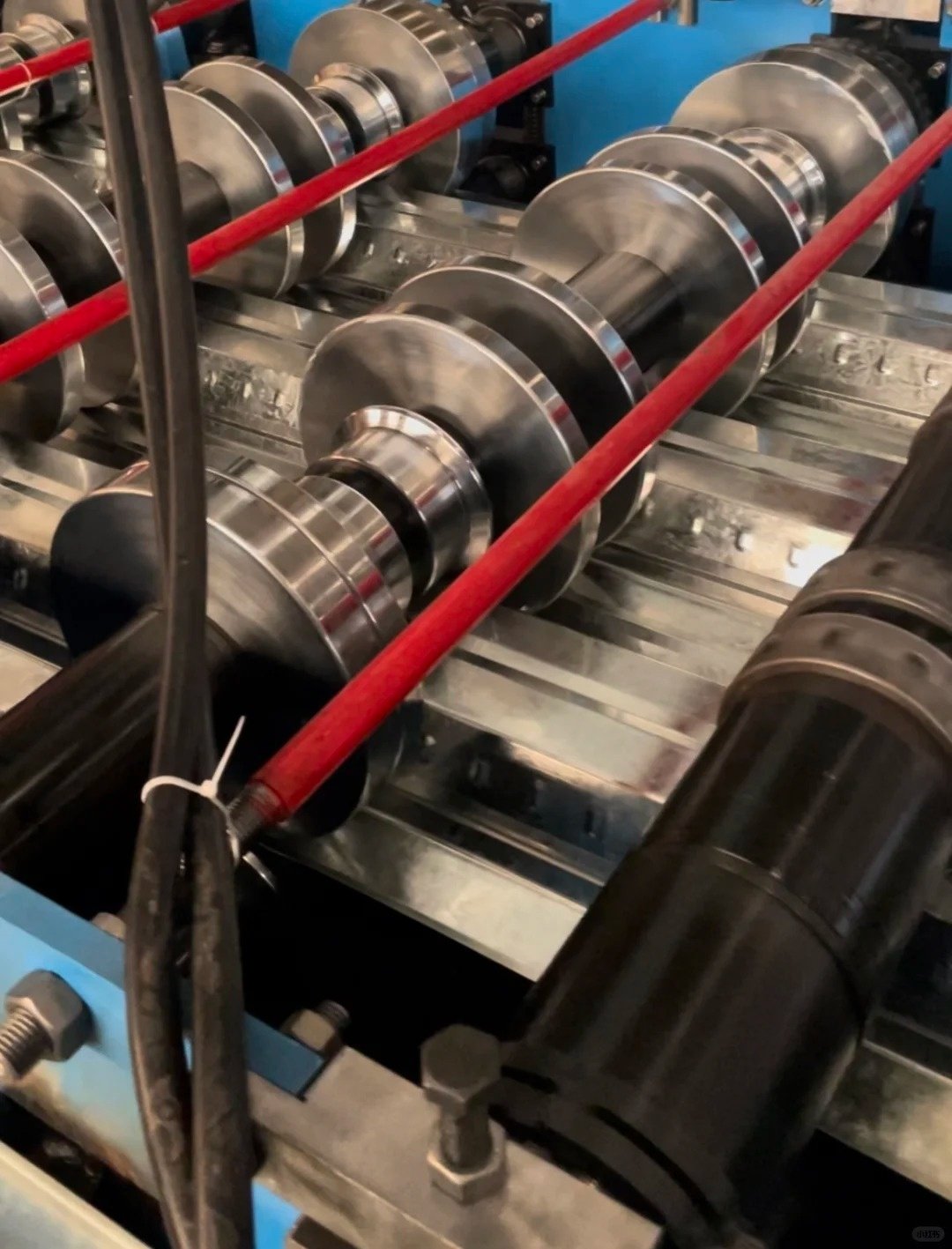

High-speed automated roll forming systems for roofing sheets, roof panels, solar mounting system and structural components.

Heavy-duty press brakes and sheet metal bending machines for complex forming applications.

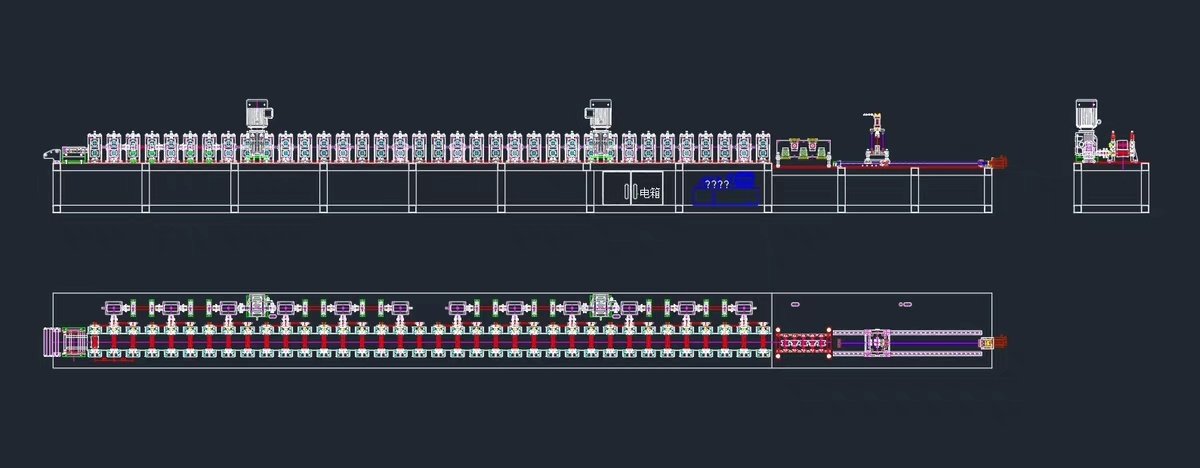

Decoiler > Leveling > Roll Forming > Post-Cut

Metal Roofing, Sheet Forming, Solar Panel Rach, Highway Guardrail, C/U/W Purlin etc.

Automation & Speed & Precision & Reliability

Smart Control & Heavy Duty & Durability

Established in 2009, LIDI Machinery has achieved a remarkable year-on-year growth rate of 36%

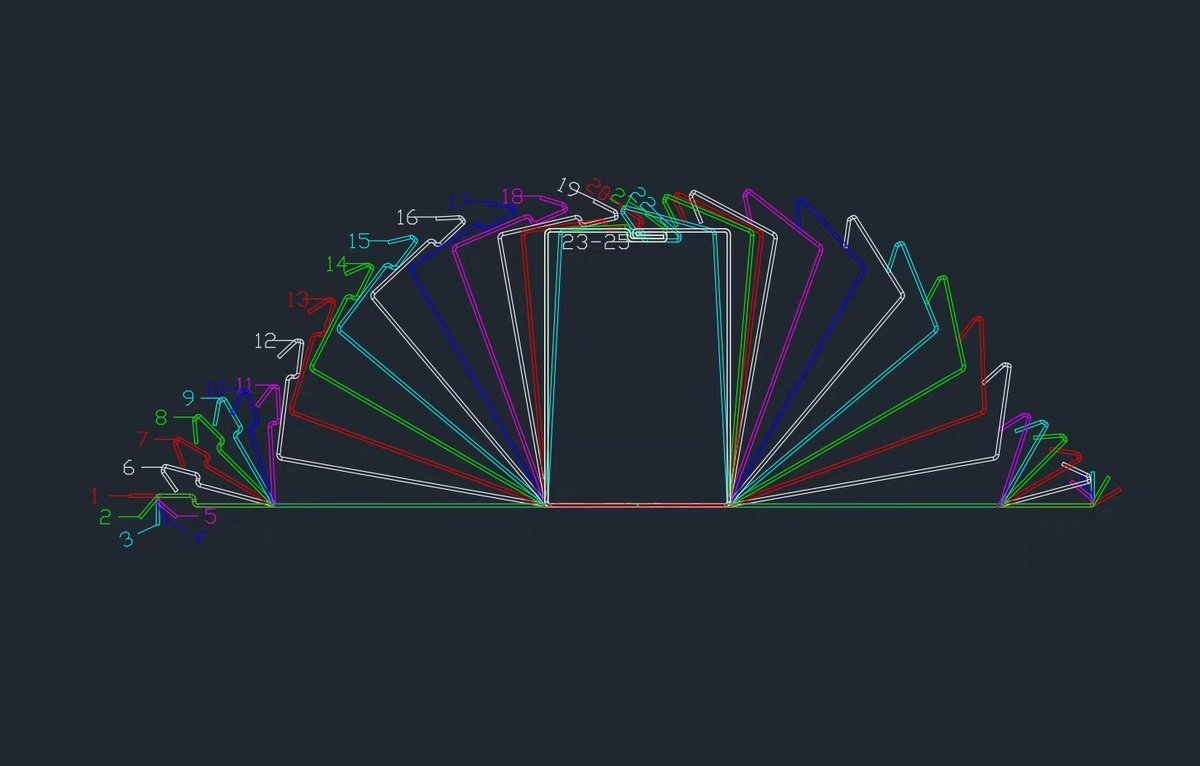

Precision 3D & 2D Drawings

CAD by Solidworks & AutoCAD enables the creation of detailed 3D parametric models of cold roll forming systems, including forming rolls, frame structures, and drive mechanisms. This ensures geometric accuracy, material optimization, and seamless assembly validation.

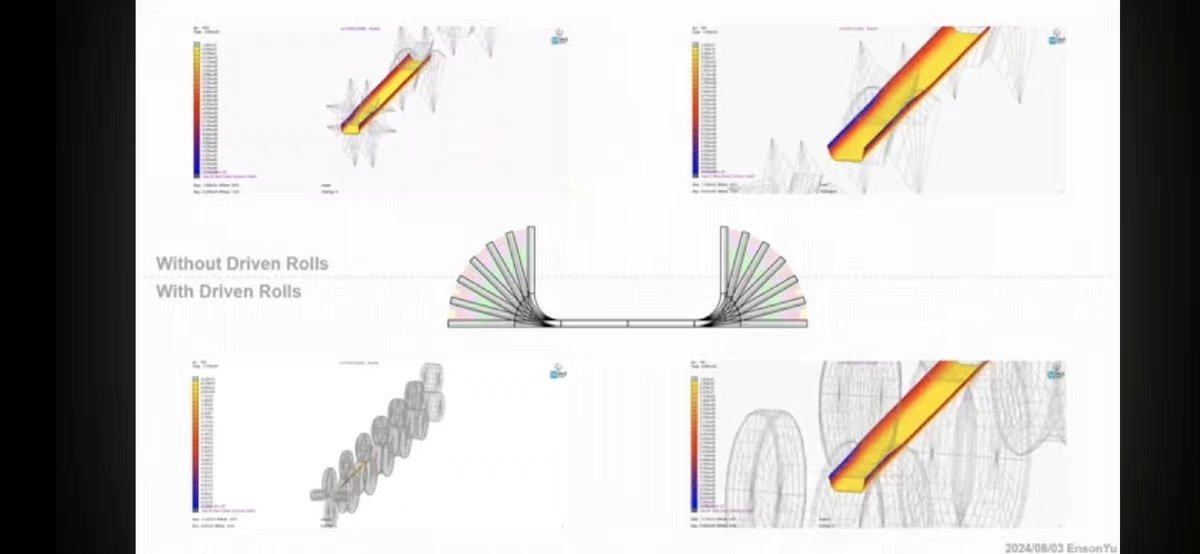

Finite Element Analysis using Abaqus & Topology Optimization

COPRA & Abaqus are used to simulate metal strip deformation dynamics, predicting stress/strain distribution, springback effects, and potential defects. OptiStruct Solver is also used to perform topology optimization which helps determine the best load path of structures.

A video simulation of how the metal get rolled into desired profile.

Our core value is customer satisfactation. We pursue long-term partnerships.

Reliability and Quality are our top priorities. Never compensate quality.

Both pre & post sales service. Life time support via video meetings.

15+ years of experience & Good knowledge ready for your project.

Over the past 15+ years we have served 400+ customers and installed 750+ machiens over the globe.

James Wilson

Production Manager, SteelTech LLC (USA)

“LIDI’s roll forming equipment enabled us to increase production efficiency by 40% while maintaining strict quality standards.”

Abdul Oladele

Project Director, West African Construction Consortium (Nigeria)

“The C/Z Purlin Production Line from LIDI Machinery has been instrumental in our Lagos shopping mall project. Despite challenging humidity conditions, the equipment maintains ±0.5mm precision – exactly what we needed for structural steel framing.”

James Mwangi

Plant Superintendent, East Africa Metalworks (Kenya)

“For our Nairobi industrial park expansion, LIDI’s cold roll forming machines reduced material waste by 15% through smart servo control. Their engineers even conducted Swahili-language training for our operators.”